Pressure Sensor Used in Hydraulic and Gas Pressure Measurement

Pressure sensors are mainly used in pressure measurement for hydraulic and gas. In the hydraulic system, the closed-loop control of force is mainly the action of the pressure sensor. Many physical and chemical properties, such as point, boiling point, vapor pressure, etc., are almost related to pressure. Gas pressure measurement is of great significance.

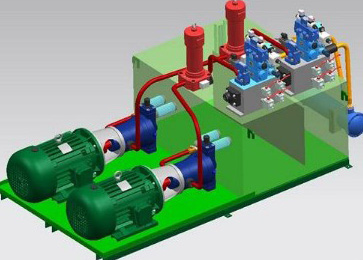

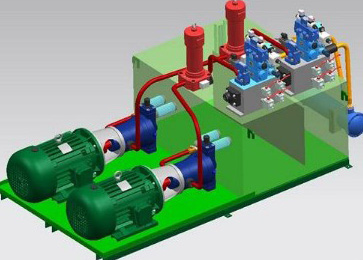

In hydraulic systems, the effect of the force is increased primarily by changing the pressure. With the development of computer and automatic control technology, the electro-hydraulic control technology of hydraulic support has also been developed. The pressure of the hydraulic system is the working power for all hydraulic actuators and the control center of most hydraulic control components. It exists in the pipeline. The pipe is sealed with hydraulic components and piping that connects the hydraulic components. The pressure in the hydraulic system reflects the working state of the hydraulic system, which can be said to be the core of the entire system.

When the liquid medium flows through the pressure sensor, the liquid pressure acts on the stainless steel of the pressure sensor housing. Then the pressure passes through the sealed silicone oil to the diffusion silicon diaphragm. The pressure at the reference end acts on the other side of the diaphragm. Therefore, the pressure difference applied to both sides of the diaphragm generates stress. One side of the diaphragm is pressed and the other side is pulled. The two corresponding slices are connected into a complete dynamic bridge to enhance the output signal.

When the control spool of the hydraulic system suddenly moves, a large force will be formed in a short time. In the use of hydraulic systems, any pressure sensor will be quickly damaged if this extreme condition is not taken into account. In addition, the pressure sensor is also subject to uninterrupted pressure pulses from the hydraulic pump. Although this pressure pulse is not as severe as the pressure peak, long-term use will cause damage to the pressure sensor.

For pressure sensors, there are mainly two ways to achieve anti-shock performance. One is to use a silicon piezoresistive pressure core, and the other is to externally connect a coil. Therefore, it is necessary to pay attention to this when selecting a pressure sensor. The pressure sensor of the model ATO-PRES-P300 uses silicon piezoresistive technology and is fully stainless steel sealed. It is small in size, good long-term stability, easy to install, economical and reliable. This pressure sensor offers new cost performance standards for low-cost, high-capacity industrial and commercial applications.

Under the proper pressure, the gas can be pressed into a small space. For the gas in the space, the pressure gradually increases as the amount of pressure increases. This state can be expressed as the gas is compressed. Conversely, if a certain amount of gas is passed into a space, the gas in this space is larger than the volume under normal conditions. These gases always fill the entire space evenly, but the pressure at this time will be lower than the pressure of the originally charged gas. This state can be expressed as gas expansion. The gas does not have a certain shape, and the gas volume is also determined by the container volume. Therefore, when preparing the theoretical preparation for industrial production, it is not enough to consider only the gas weight. Considering the gas weight, it is also necessary to consider how much it occupies.

The ATO-PRES-P400 pressure sensor is suitable for liquid and gas pressure measurement, even for medium such as sewage, oil and corrosive liquids. The pressure chamber of the ATO-PRES-P400 is machined from 316L stainless steel, using the classic 2088 type head. A variety of thread of pressure connections are available for selection or customization. Range -0.1~60MPa / -1~600bar / -14~8702psi, users can select according to actual needs. It is extremely durable and can be used in wet or harsh environments for a long time.

- Pressure sensor used in hydraulic system

In hydraulic systems, the effect of the force is increased primarily by changing the pressure. With the development of computer and automatic control technology, the electro-hydraulic control technology of hydraulic support has also been developed. The pressure of the hydraulic system is the working power for all hydraulic actuators and the control center of most hydraulic control components. It exists in the pipeline. The pipe is sealed with hydraulic components and piping that connects the hydraulic components. The pressure in the hydraulic system reflects the working state of the hydraulic system, which can be said to be the core of the entire system.

When the liquid medium flows through the pressure sensor, the liquid pressure acts on the stainless steel of the pressure sensor housing. Then the pressure passes through the sealed silicone oil to the diffusion silicon diaphragm. The pressure at the reference end acts on the other side of the diaphragm. Therefore, the pressure difference applied to both sides of the diaphragm generates stress. One side of the diaphragm is pressed and the other side is pulled. The two corresponding slices are connected into a complete dynamic bridge to enhance the output signal.

When the control spool of the hydraulic system suddenly moves, a large force will be formed in a short time. In the use of hydraulic systems, any pressure sensor will be quickly damaged if this extreme condition is not taken into account. In addition, the pressure sensor is also subject to uninterrupted pressure pulses from the hydraulic pump. Although this pressure pulse is not as severe as the pressure peak, long-term use will cause damage to the pressure sensor.

For pressure sensors, there are mainly two ways to achieve anti-shock performance. One is to use a silicon piezoresistive pressure core, and the other is to externally connect a coil. Therefore, it is necessary to pay attention to this when selecting a pressure sensor. The pressure sensor of the model ATO-PRES-P300 uses silicon piezoresistive technology and is fully stainless steel sealed. It is small in size, good long-term stability, easy to install, economical and reliable. This pressure sensor offers new cost performance standards for low-cost, high-capacity industrial and commercial applications.

- Pressure sensors used in gas pressure measurement

Under the proper pressure, the gas can be pressed into a small space. For the gas in the space, the pressure gradually increases as the amount of pressure increases. This state can be expressed as the gas is compressed. Conversely, if a certain amount of gas is passed into a space, the gas in this space is larger than the volume under normal conditions. These gases always fill the entire space evenly, but the pressure at this time will be lower than the pressure of the originally charged gas. This state can be expressed as gas expansion. The gas does not have a certain shape, and the gas volume is also determined by the container volume. Therefore, when preparing the theoretical preparation for industrial production, it is not enough to consider only the gas weight. Considering the gas weight, it is also necessary to consider how much it occupies.

The ATO-PRES-P400 pressure sensor is suitable for liquid and gas pressure measurement, even for medium such as sewage, oil and corrosive liquids. The pressure chamber of the ATO-PRES-P400 is machined from 316L stainless steel, using the classic 2088 type head. A variety of thread of pressure connections are available for selection or customization. Range -0.1~60MPa / -1~600bar / -14~8702psi, users can select according to actual needs. It is extremely durable and can be used in wet or harsh environments for a long time.