What is a Pressure Sensor

A pressure sensor is a device or equipment that senses a pressure signal and converts the pressure signal into a usable output electrical signal according to a certain law.

The pressure sensor are usually composed of pressure sensitive components and signal processing units. According to different measured pressure types, the pressure sensor are generally divided into absolute pressure sensors, differential pressure sensors and gauge pressure sensors.

Absolute pressure refers to all the pressure in the space in which the medium (liquid, gas or steam) is located, which is the pressure relative to zero pressure. Complete vacuum is a condition in which no substance is present in the atmosphere, so there is zero pressure in this area. The use of absolute pressure sensors is limited because it is impossible to achieve a perfect vacuum. Therefore, Sensors based on absolute pressure measurements require rigorous and accurate output specifications. Absolute pressure sensors are typically used for atmospheric pressure or altitude related pressure measurements.

II. Differential pressure measurement

In differential pressure measurements, the measured pressure are pressures at different locations or pressures of different medium. This measurement type is used for pressure monitoring to monitor fluid and flowing medium and maintaining flow uniformity. In various types of purification systems, differential pressure measurement has important applications in filter monitoring, which take into account the normal pressure of the filter when it cleaning the fluid. When the filter is blocked by pollutants, the differential pressure sensor gives a reading relative to normal pressure, which helps keep the filter clean and proper.

III. Gauge pressure measurement

Gauge pressure refers to the value of the total absolute pressure above the ambient atmospheric pressure or the pressure at a point in the liquid above atmospheric pressure. Gauge pressure measurement can be defined as a sub-type of differential pressure measurement, which generally compare the measured pressure to the current atmospheric pressure. A gauge pressure sensor is a sensor that senses pressure relative to ambient pressure and converts it into a usable output signal.

According to different working principles, it can be divided into many types of sensors, the most common type are diffused silicon pressure sensor and monocrystalline silicon pressure sensor fabricated on the principle of piezoresistive effect.

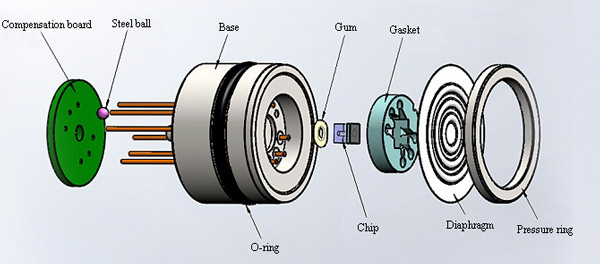

The diffused silicon pressure sensor is fabricated by encapsulating the isolated silicon piezoresistive pressure sensitive component in a stainless steel housing. It converts the measured pressure of liquid or gas into a standard electrical signal for external output. Diffused silicon pressure sensors are widely used in on-site measurement and control of industrial processes such as water supply and drainage, heat, petroleum, chemical, and metallurgy. Diffusion silicon technology is a sensor technology that has gradually developed with the growing maturity of semiconductor microelectromechanical technology and other materials as well as auxiliary production technologies in the latter part of the last century.

II. What is the diffused silicon

Diffused silicon core is the core component of the pressure sensor. As a high-performance primary pressure measurement product, it can be easily used in signal amplification and it can be assembled into a device that outputs standard signals. Diffused silicon is widely used in process control in petroleum, chemical, metallurgical, electric power, aerospace, medical equipment, automotive, HVAC and other industries.

The diffused silicon circuit board adopts a new type of amplifying circuit, and selects chip components with good performance, which has higher accuracy, stability and overload pressure than other similar products. It adapt to a variety of pressure sensors such as diffused silicon and strain gauges. Diffused silicon can be combined with a dedicated pressure sensor housing to form an integrated pressure sensor, or it can be installed separately.

III. Diffused silicon pressure sensor working principle

The pressure of the measuring medium directly acts on the diaphragm of the sensor (stainless steel or ceramic) to cause the diaphragm to generate a micro-displacement proportional to the medium pressure, so that the resistance value of the sensor changes. Then the change detected by the electronic circuit, at the same time, it converts and outputs a standard measurement signal corresponding to this pressure.

The diffused silicon pressure sensor converts the pressure signal into an electrical signal through the transmitter, and then the preamplifier amplifies and filters the electrical signal, then sends it to the A/D conversion module of the CPU for analog to digital conversion. Finally, the CPU performs data processing and display as well as PWM output. The principle block diagram is as follows:

Measured medium→ Pressure sensor→ Electronic circuit→ Output signal

The pressure of the measured medium directly acts on the diffused silicon diaphragm of the sensor, causing the diaphragm to produce a minor displacement proportional to the medium pressure. Under normal working conditions, the maximum displacement of the diaphragm is not more than 0.025 mm. After the electronic circuit detect this displacement, it converts this displacement into a standard industrial measurement signal corresponding to this pressure. When overpressure, the diaphragm will attach directly to the strong diffused silicon of the substrate. Since the gap between the diaphragm and the substrate is only 0.1 mm, the maximum displacement of the diaphragm in overpressure is only 0.1 mm. It structurally ensures that the diaphragm does not undergo excessive deformation, and make the sensor has good stability and high reliability.

IV. Silicon Oil in Diffused Silicon Pressure Sensor

In the production of diffused silicon pressure sensors, silicon oil is used as a pressure medium and fill fluid to protect the pressure sensor chip. Silicone oil is a polyorganosiloxane with different polymerization degree and chain structure. According to different pressure measurement occasions, it is necessary to fill different properties of silicon oil, such as high temperature silicon oil, low temperature silicon oil and conventional silicon oil. The silicon oil is obtained by hydrolysis of dimethyldichlorosilane with water to obtain a polycondensation ring, and the ring body is subjected to pyrolysis and rectification to obtain a low ring body. Then, the ring body, the heading agent and the catalyst are put together for telomerization to obtain a mixture of various polymerization degrees. Finally, the silicon oil can be obtained by vacuum distillation and removing low boilers.

According to different pressure measurement occasions, it is necessary to fill different properties of silicon oil, such as high temperature silicon oil, low temperature silicon oil and conventional silicon oil. The silicon oil is obtained by hydrolysis of dimethyldichlorosilane with water to obtain a polycondensation ring, and the ring body is subjected to pyrolysis and rectification to obtain a low ring body. Then, the ring body, the heading agent and the catalyst are put together for telomerization to obtain a mixture of various polymerization degrees. Finally, the silicon oil can be obtained by vacuum distillation and removing low boilers.

Generally silicon oil is colorless (or light yellow), odorless, non-toxic and non-volatile liquid. Silicone oil is insoluble in water, methanol and glycol, and is miscible with benzene, dimethyl ether, methyl ethyl ketone, carbon tetrachloride or kerosene, slightly soluble in acetone, dioxane, ethanol and butanol. It has a small vapor pressure, a high flash point and flash point, and a low freezing point. As the number of segments n varies, the molecular weight increases and the viscosity increases. Therefore, silicone oil can have different viscosities, from 0.65 centistokes to millions of centistokes. If it needs to produce low viscosity silicon oil, acid clay can be used as a catalyst and perform telomerization at 180 °C. If it needs to produce high viscosity silicon oil, sulfuric acid can be used as a catalyst to modulate at a low temperature to produce the high viscosity silicone oil.

Silicon oil has excellent heat resistance, electrical insulation, weather resistance, hydrophobicity, physiological inertness and low surface tension. In addition, silicone oil has lower viscosity temperature coefficient and higher compression resistance. Some varieties also have radiation resistance.

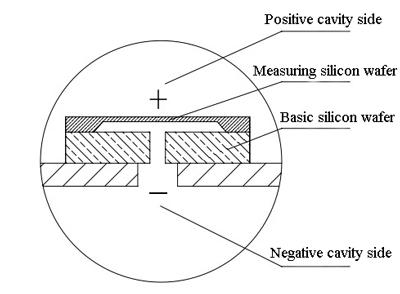

The module of the monocrystalline silicon pressure sensor uses all-welding technology and has an integrated overload diaphragm inside. The positive pressure side of the sensor is connected to the high pressure chamber of the bellows, and the negative pressure side is connected to the low pressure chamber of the bellows. The pressure is transmitted to the silicon chip in the sensor through the isolation diaphragm and the filling liquid, so that the resistance value of the pressure sensor chip changes, thereby causing the detection system output voltage to change. The output voltage is proportional to the pressure change and is converted by the adaptation unit and amplifier into a standardized signal output.

II. Monocrystalline silicon pressure sensor working principle

The monocrystalline silicon pressure sensor utilizes the piezoresistive effect of monocrystalline silicon. It uses monocrystalline silicon wafers as elastic components. On the monocrystalline silicon diaphragm, an integrated circuit is used to spread a set of equivalent resistance in a specific direction of the monocrystalline silicon, and the resistor is connected into a bridge, and the monocrystalline silicon wafer is placed in the monocrystalline silicon pressure sensor cavity. When the pressure changes, the monocrystalline silicon strains, so that the strain resistance directly diffused on it produces a change proportional to the measured pressure, and the corresponding voltage output signal is obtained by the bridge circuit.

The pressure sensor are usually composed of pressure sensitive components and signal processing units. According to different measured pressure types, the pressure sensor are generally divided into absolute pressure sensors, differential pressure sensors and gauge pressure sensors.

- Pressure type measured by pressure sensor

Absolute pressure refers to all the pressure in the space in which the medium (liquid, gas or steam) is located, which is the pressure relative to zero pressure. Complete vacuum is a condition in which no substance is present in the atmosphere, so there is zero pressure in this area. The use of absolute pressure sensors is limited because it is impossible to achieve a perfect vacuum. Therefore, Sensors based on absolute pressure measurements require rigorous and accurate output specifications. Absolute pressure sensors are typically used for atmospheric pressure or altitude related pressure measurements.

II. Differential pressure measurement

In differential pressure measurements, the measured pressure are pressures at different locations or pressures of different medium. This measurement type is used for pressure monitoring to monitor fluid and flowing medium and maintaining flow uniformity. In various types of purification systems, differential pressure measurement has important applications in filter monitoring, which take into account the normal pressure of the filter when it cleaning the fluid. When the filter is blocked by pollutants, the differential pressure sensor gives a reading relative to normal pressure, which helps keep the filter clean and proper.

III. Gauge pressure measurement

Gauge pressure refers to the value of the total absolute pressure above the ambient atmospheric pressure or the pressure at a point in the liquid above atmospheric pressure. Gauge pressure measurement can be defined as a sub-type of differential pressure measurement, which generally compare the measured pressure to the current atmospheric pressure. A gauge pressure sensor is a sensor that senses pressure relative to ambient pressure and converts it into a usable output signal.

According to different working principles, it can be divided into many types of sensors, the most common type are diffused silicon pressure sensor and monocrystalline silicon pressure sensor fabricated on the principle of piezoresistive effect.

- Diffused silicon pressure sensor

The diffused silicon pressure sensor is fabricated by encapsulating the isolated silicon piezoresistive pressure sensitive component in a stainless steel housing. It converts the measured pressure of liquid or gas into a standard electrical signal for external output. Diffused silicon pressure sensors are widely used in on-site measurement and control of industrial processes such as water supply and drainage, heat, petroleum, chemical, and metallurgy. Diffusion silicon technology is a sensor technology that has gradually developed with the growing maturity of semiconductor microelectromechanical technology and other materials as well as auxiliary production technologies in the latter part of the last century.

II. What is the diffused silicon

Diffused silicon core is the core component of the pressure sensor. As a high-performance primary pressure measurement product, it can be easily used in signal amplification and it can be assembled into a device that outputs standard signals. Diffused silicon is widely used in process control in petroleum, chemical, metallurgical, electric power, aerospace, medical equipment, automotive, HVAC and other industries.

The diffused silicon circuit board adopts a new type of amplifying circuit, and selects chip components with good performance, which has higher accuracy, stability and overload pressure than other similar products. It adapt to a variety of pressure sensors such as diffused silicon and strain gauges. Diffused silicon can be combined with a dedicated pressure sensor housing to form an integrated pressure sensor, or it can be installed separately.

III. Diffused silicon pressure sensor working principle

The pressure of the measuring medium directly acts on the diaphragm of the sensor (stainless steel or ceramic) to cause the diaphragm to generate a micro-displacement proportional to the medium pressure, so that the resistance value of the sensor changes. Then the change detected by the electronic circuit, at the same time, it converts and outputs a standard measurement signal corresponding to this pressure.

The diffused silicon pressure sensor converts the pressure signal into an electrical signal through the transmitter, and then the preamplifier amplifies and filters the electrical signal, then sends it to the A/D conversion module of the CPU for analog to digital conversion. Finally, the CPU performs data processing and display as well as PWM output. The principle block diagram is as follows:

Measured medium→ Pressure sensor→ Electronic circuit→ Output signal

The pressure of the measured medium directly acts on the diffused silicon diaphragm of the sensor, causing the diaphragm to produce a minor displacement proportional to the medium pressure. Under normal working conditions, the maximum displacement of the diaphragm is not more than 0.025 mm. After the electronic circuit detect this displacement, it converts this displacement into a standard industrial measurement signal corresponding to this pressure. When overpressure, the diaphragm will attach directly to the strong diffused silicon of the substrate. Since the gap between the diaphragm and the substrate is only 0.1 mm, the maximum displacement of the diaphragm in overpressure is only 0.1 mm. It structurally ensures that the diaphragm does not undergo excessive deformation, and make the sensor has good stability and high reliability.

IV. Silicon Oil in Diffused Silicon Pressure Sensor

In the production of diffused silicon pressure sensors, silicon oil is used as a pressure medium and fill fluid to protect the pressure sensor chip. Silicone oil is a polyorganosiloxane with different polymerization degree and chain structure.

Generally silicon oil is colorless (or light yellow), odorless, non-toxic and non-volatile liquid. Silicone oil is insoluble in water, methanol and glycol, and is miscible with benzene, dimethyl ether, methyl ethyl ketone, carbon tetrachloride or kerosene, slightly soluble in acetone, dioxane, ethanol and butanol. It has a small vapor pressure, a high flash point and flash point, and a low freezing point. As the number of segments n varies, the molecular weight increases and the viscosity increases. Therefore, silicone oil can have different viscosities, from 0.65 centistokes to millions of centistokes. If it needs to produce low viscosity silicon oil, acid clay can be used as a catalyst and perform telomerization at 180 °C. If it needs to produce high viscosity silicon oil, sulfuric acid can be used as a catalyst to modulate at a low temperature to produce the high viscosity silicone oil.

Silicon oil has excellent heat resistance, electrical insulation, weather resistance, hydrophobicity, physiological inertness and low surface tension. In addition, silicone oil has lower viscosity temperature coefficient and higher compression resistance. Some varieties also have radiation resistance.

- Monocrystalline silicon pressure sensor

The module of the monocrystalline silicon pressure sensor uses all-welding technology and has an integrated overload diaphragm inside. The positive pressure side of the sensor is connected to the high pressure chamber of the bellows, and the negative pressure side is connected to the low pressure chamber of the bellows. The pressure is transmitted to the silicon chip in the sensor through the isolation diaphragm and the filling liquid, so that the resistance value of the pressure sensor chip changes, thereby causing the detection system output voltage to change. The output voltage is proportional to the pressure change and is converted by the adaptation unit and amplifier into a standardized signal output.

II. Monocrystalline silicon pressure sensor working principle

The monocrystalline silicon pressure sensor utilizes the piezoresistive effect of monocrystalline silicon. It uses monocrystalline silicon wafers as elastic components. On the monocrystalline silicon diaphragm, an integrated circuit is used to spread a set of equivalent resistance in a specific direction of the monocrystalline silicon, and the resistor is connected into a bridge, and the monocrystalline silicon wafer is placed in the monocrystalline silicon pressure sensor cavity. When the pressure changes, the monocrystalline silicon strains, so that the strain resistance directly diffused on it produces a change proportional to the measured pressure, and the corresponding voltage output signal is obtained by the bridge circuit.