Digital Pressure Transducer for Air/Steam/Hydraulic

The digital pressure transducer has a LCD screen with backlight, which can display pressure values in real time. It uses DC 24V / 12V as the power source, converts the pressure signal into current signal (4-20mA / 0-20mA), voltage signal (0-5V / 1-5V / 0-10V) or RS485 signal to output. The pressure transducer is small in size, light in weight, and has high anti-vibration and anti-shock performance. It can measure the pressure for air, steam, hydraulic and high temperature liquids. Measuring range -0.1~100MPa / -1~1000bar / -14~14503psi, medium temperature -40~ +60℃ (-40~ + 140℉).

The digital pressure transducer has a LCD screen with backlight, which can display pressure values in real time. It uses DC 24V / 12V as the power source, converts the pressure signal into current signal (4-20mA / 0-20mA), voltage signal (0-5V / 1-5V / 0-10V) or RS485 signal to output. The pressure transducer is small in size, light in weight, and has high anti-vibration and anti-shock performance. It can measure the pressure for air, steam, hydraulic and high temperature liquids. Measuring range -0.1~100MPa / -1~1000bar / -14~14503psi, medium temperature -40~ +60℃ (-40~ + 140℉).Tips: In the linear range of the pressure transducer, the higher the sensitivity, the better the measurement result. For pressure transducer with high sensitivity, the output signal corresponding to the pressure change is more pronounced, which is advantageous for signal transmission. However, if the pressure transducer sensitivity is too high, external noise unrelated to the measurement will be mixed in. These noises will also be amplified by the amplification system, which affects the measurement accuracy. Therefore, digital pressure transducers should have a high signal-to-noise ratio to minimize external interference signals.

For digital pressure transducers, the sensitivity is directional. When the measured quantity is a single vector and its direction requirement is high, a pressure transducer with a lower sensitivity in other directions should be selected. If the measured quantity is a multidimensional vector, a digital pressure transducer with a small cross sensitivity should be selected.

Digital pressure transducer specification

|

Model |

ATO-PRES-PX300 |

|

Weight |

0.4kg |

|

Measuring range |

-0.1~100MPa (-1~1000bar/-14~14503psi) |

|

Pressure type |

Gauge pressure, absolute pressure, sealed pressure |

|

Measure medium |

Hydraulic, steam, air, high-temperature liquid (non-explosion proof area) |

|

Power supply |

DC 12V, DC 24V, DC 12-36V |

|

Output signal |

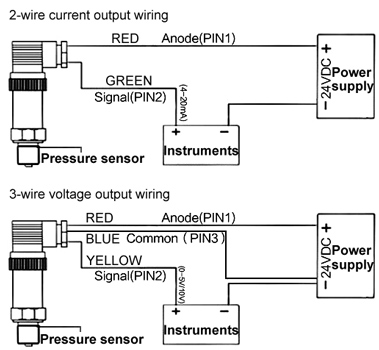

2 wire: 4-20mA, 0-20mA 3 wire: 0-5V, 1-5V, 0-10V RS485 |

|

Accuracy |

±0.5%FS, ±0.3%FS |

|

Zero temperature drift |

±0.03%FS/℃ |

|

Sensitivity temperature drift |

±0.03%FS/℃ |

|

Long term stability |

≤0.2%FS/year |

|

Overload pressure |

200%FS |

|

Frequency response (-3dB) |

5kHz~650kHz |

|

Electrical connection |

DIN connector type, M12 circuilar connector type, direct lead wire type |

|

Thread of pressure connection |

G1/4, G1/2, 1/4NPT, 1/2NPT, M14*1.5, M20*1.5 |

|

Response time |

<10ms |

|

Operating temperature |

-40~+80℃ (-40~+176℉) |

|

Medium temperature |

-40~+60℃ (-40~+140℉) |

|

Material |

Housing: 304/316L stainless steel Fill fluid: silicon oil Pressure port: 304/316L stainless steel Separating diaphragm: 304/316L stainless steel Sealing: FKM (medium temperature ≤ +200℃/+392℉), EPDM, NBR |

|

Cable length |

2m |

|

Protection class |

IP65 |

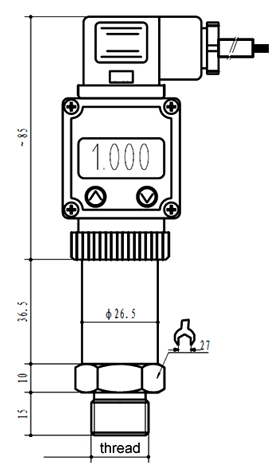

Digital pressure transducer dimension drawing

Digital pressure transducer wiring diagram