Pressure Transducer and Level Sensor in Liquid Level Measurement

In liquid level measurement, the pressure transducer and the liquid level sensor are two sensors that are commonly used in various types of equipment or projects. The measurement principle of these two sensors are the same. Although the two sensors are similar, there are some differences. This paper explains the difference between the pressure transducer and the liquid level sensor in liquid level measurement in principle, classification and application.

The difference between the pressure transducer and the liquid level sensor in liquid level measurement

1. Measuring principle of pressure transducer and liquid level sensor

For use of both pressure transducers and liquid level sensors, they all be put into set depth of the measured liquid of the sensor. The pressure at which the measuring point of the sensor directly contacts the liquid surface are the same. The formula is:

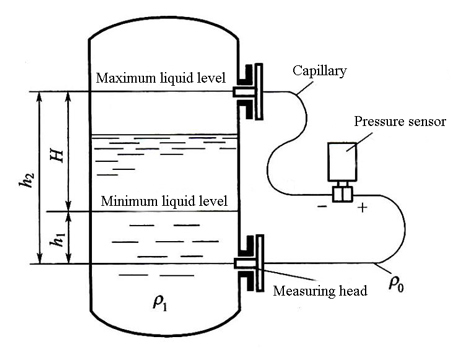

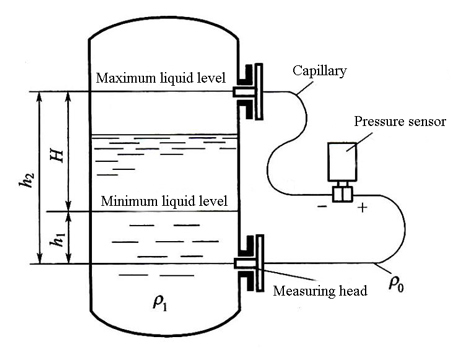

P=ρ×g×H+P0

In the formula, P is the pressure when the measurement point of liquid level sensor directly contacts the liquid surface; ρ is the density of the measured liquid; g is the gravitational acceleration (calculated at 9.8015 m/s2 during debugging); P0 is the atmospheric pressure on the liquid surface; H is the depth at which the sensor is inserted into the liquid. At the same time, introduce the liquid pressure into the positive pressure chamber of the sensor through a stainless steel air tube. Then connect the atmospheric pressure P0 on the liquid surface to the negative pressure chamber of the sensor. It can offset the P0 on the back of the sensor, and the pressure measured by the sensor is ρ×g×H. Obviously, by measuring the pressure P, the liquid level depth can be obtained. The difference is that the pressure transducer outputs the pressure P, while the liquid level sensor outputs the depth H.

2. Liquid level measurement

2.1 Mechanical height method

The mechanical transmission structure is complex, and the vertical angle of the instrument will affect the measurement accuracy. In the cold winter, it is easy for the transmission machinery to freeze and not move. Moreover, this method uses the pen to draw the simulation curve or manual reading, which is not conducive to automation and computer communication.

2.2 pressure measurement method

The method uses a pressure transducer buried in the bottom of the liquid or buried at a certain depth to measure the pressure. Use the formula Pa=ρ×C×H to get the height of the liquid level. Then we can obtain the container capacity at the corresponding height, that is, the volume of the contained liquid, according to the structure size of the container. The pressure transducer outputs an electrical signal proportional to the pressure. This signal can be transmitted over long distance. It is easy to record automatically and further improve accuracy for correction and compensation in the processor.

3. Classification of pressure transducers and liquid level sensors

The classification of the two is different. The pressure transducer is generally classified into monocrystalline silicon pressure transducers, diffused silicon pressure transducers, strain gauge pressure transducers, ceramic pressure transducers, piezoelectric pressure transducers, and the like. The liquid level sensor is generally divided into a float type liquid level sensor, a float type liquid level sensor, and a static pressure type liquid level sensor.

4. Application of pressure transducer in liquid level measurement

In industrial production and transportation, liquid level monitoring and measurement can be seen everywhere. For example, the water level in the boiler, the liquid level of the container in chemical production. When the ship enter the port, it is necessary to detect the water depth and the draft depth of the ship itself. Sometimes, for production needs, the liquid level measurement is converted into the amount and density of liquid stored in the container.

In summary, it can be said that the liquid level sensor is an extension of the function of the pressure transducer. In many cases, with a slight change, the pressure transducer and liquid level sensor can in common use. As the technology development and the change of use environment, the division of labor between pressure transducers and liquid level sensors will become more detailed.

The difference between the pressure transducer and the liquid level sensor in liquid level measurement

1. Measuring principle of pressure transducer and liquid level sensor

For use of both pressure transducers and liquid level sensors, they all be put into set depth of the measured liquid of the sensor. The pressure at which the measuring point of the sensor directly contacts the liquid surface are the same. The formula is:

P=ρ×g×H+P0

In the formula, P is the pressure when the measurement point of liquid level sensor directly contacts the liquid surface; ρ is the density of the measured liquid; g is the gravitational acceleration (calculated at 9.8015 m/s2 during debugging); P0 is the atmospheric pressure on the liquid surface; H is the depth at which the sensor is inserted into the liquid. At the same time, introduce the liquid pressure into the positive pressure chamber of the sensor through a stainless steel air tube. Then connect the atmospheric pressure P0 on the liquid surface to the negative pressure chamber of the sensor. It can offset the P0 on the back of the sensor, and the pressure measured by the sensor is ρ×g×H. Obviously, by measuring the pressure P, the liquid level depth can be obtained. The difference is that the pressure transducer outputs the pressure P, while the liquid level sensor outputs the depth H.

2. Liquid level measurement

2.1 Mechanical height method

The mechanical transmission structure is complex, and the vertical angle of the instrument will affect the measurement accuracy. In the cold winter, it is easy for the transmission machinery to freeze and not move. Moreover, this method uses the pen to draw the simulation curve or manual reading, which is not conducive to automation and computer communication.

2.2 pressure measurement method

The method uses a pressure transducer buried in the bottom of the liquid or buried at a certain depth to measure the pressure. Use the formula Pa=ρ×C×H to get the height of the liquid level. Then we can obtain the container capacity at the corresponding height, that is, the volume of the contained liquid, according to the structure size of the container. The pressure transducer outputs an electrical signal proportional to the pressure. This signal can be transmitted over long distance. It is easy to record automatically and further improve accuracy for correction and compensation in the processor.

3. Classification of pressure transducers and liquid level sensors

The classification of the two is different. The pressure transducer is generally classified into monocrystalline silicon pressure transducers, diffused silicon pressure transducers, strain gauge pressure transducers, ceramic pressure transducers, piezoelectric pressure transducers, and the like. The liquid level sensor is generally divided into a float type liquid level sensor, a float type liquid level sensor, and a static pressure type liquid level sensor.

4. Application of pressure transducer in liquid level measurement

In industrial production and transportation, liquid level monitoring and measurement can be seen everywhere. For example, the water level in the boiler, the liquid level of the container in chemical production. When the ship enter the port, it is necessary to detect the water depth and the draft depth of the ship itself. Sometimes, for production needs, the liquid level measurement is converted into the amount and density of liquid stored in the container.

In summary, it can be said that the liquid level sensor is an extension of the function of the pressure transducer. In many cases, with a slight change, the pressure transducer and liquid level sensor can in common use. As the technology development and the change of use environment, the division of labor between pressure transducers and liquid level sensors will become more detailed.