Hydraulic Pressure Sensor Applications in Water Distribution

The hydraulic pressure sensor are common applications in most modern water distribution systems. In current industrial applications, pressure sensors and digital pressure gauges are the two most widely used in water distribution systems. A pressure gauge is a meter that measures and indicates fluid pressure with a resilient element as a sensitive component. Pressure gauges have existed for centuries and have proven to be accurate and reliable. Compared to the characteristics of the pressure gauge not outputting the signal, the pressure sensor converts the measured pressure into a standard current signal output.

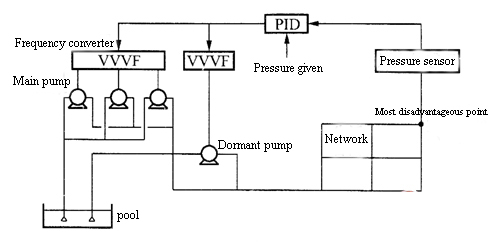

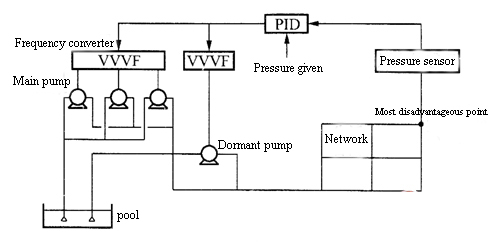

The water distribution system is a combination of water intake, water delivery, water treatment, and water supply in a certain way. It is a network that transports water systematically to the water use location through pipelines and ancillary equipment. Its principle is to meet the demands of building or users in production, living and fire protection. The pressure measured by the hydraulic pressure sensor can be a function of static water pressure or dynamic water pressure. An example of static water pressure is to measure the water level in the storage tank. An example of dynamic water pressure is to measure the water pressure of a water pipe in a water distribution system to monitor transient pressure or pipe burst.

The data measured by a typical hydraulic pressure sensor includes flow and pressure. Hydraulic pressure sensors can be used in conjunction with data acquisition systems, hydraulic computer models, or both to provide a means of analyzing real-time or predicted hydraulic specifications in a water distribution system. The hydraulic sensor is connected to the RTU/PLC via hardwire or wireless and transmits hydraulic data through the communication network according to requirements or within the set intervals. These data will eventually appear in the HMI and / or SCADA master system and submitted to the end user for analysis, or compiled in the Historian (database system), in which these data can be accessed to predict demand patterns, assess system efficiency, and analyze system head deficiencies.

Data of the pressure sensor plays an important role in the management of water distribution systems. The use of data includes, but is not limited to, the following aspects.

The water distribution system is a combination of water intake, water delivery, water treatment, and water supply in a certain way. It is a network that transports water systematically to the water use location through pipelines and ancillary equipment. Its principle is to meet the demands of building or users in production, living and fire protection. The pressure measured by the hydraulic pressure sensor can be a function of static water pressure or dynamic water pressure. An example of static water pressure is to measure the water level in the storage tank. An example of dynamic water pressure is to measure the water pressure of a water pipe in a water distribution system to monitor transient pressure or pipe burst.

- Use of hydraulic sensor data

The data measured by a typical hydraulic pressure sensor includes flow and pressure. Hydraulic pressure sensors can be used in conjunction with data acquisition systems, hydraulic computer models, or both to provide a means of analyzing real-time or predicted hydraulic specifications in a water distribution system. The hydraulic sensor is connected to the RTU/PLC via hardwire or wireless and transmits hydraulic data through the communication network according to requirements or within the set intervals. These data will eventually appear in the HMI and / or SCADA master system and submitted to the end user for analysis, or compiled in the Historian (database system), in which these data can be accessed to predict demand patterns, assess system efficiency, and analyze system head deficiencies.

Data of the pressure sensor plays an important role in the management of water distribution systems. The use of data includes, but is not limited to, the following aspects.

- Ensure adequate water supply to industry, schools and other key users in systems or supply water and extinguishing.

- Identify the water amount on the ground and overhead tanks.

- Detect major water loss events.

- Plan maintenance and flushing for fire hydrants.

- Verify the TEM hydraulic model in water distribution system and.

- Verify the water quality modeling in water distribution system and.

- Determine the valve problem of the water distribution system.

- Provide data for components used in the Contaminant Warning System (CWS).

- Help managers understand the flow and pressure in the water distribution system to analyze water quality issues and ensure proper system pressure.