Use Differential Pressure Transducer Measure Liquid Level

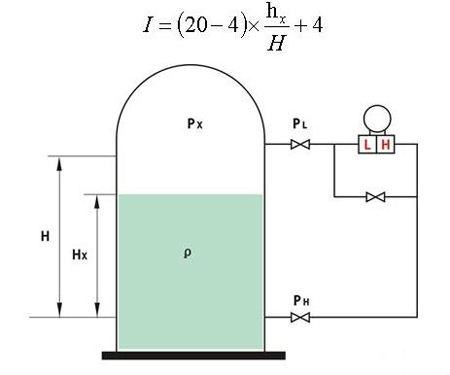

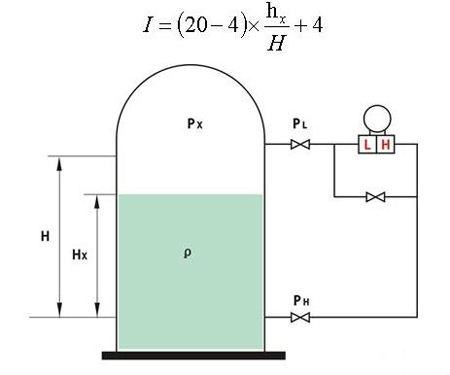

It is difficult for a differential pressure transducer to measure the

level of a cryogenic liquid below -20 ℃. If we need to measure the

liquid level of low temperature medium such as liquid ammonia and liquid

nitrogen, we can use indirect measurement by gas isolation. As shown in

the figure, the purpose for measuring the liquid level of the low

temperature medium is achieved by measuring the gas pressure in the

pressure guiding tube. Since the liquid in the pressure guiding tube on

the high pressure side is at a normal temperature state above the

boiling point, the liquid in the pressure guiding tube evaporates into a

gas until a saturated gas is formed in the pressure guiding tube. When

selecting a differential pressure transducer for measurement, the method

uses the principle of liquid column static pressure. At this time, the

pressures on the high and low pressure sides in the differential

pressure transducer are as follows respectively:

PH=Hx × ρ + Px ; PL=Px

P=PH + PL=(Hx × ρ + Px ) - Px=Hx × ρ, its range: ∆P=(Hx × ρ + Px), then the correspondence between the differential pressure and the current is as follows.

The differential pressure transducer should be installed at a position higher than the highest liquid level, and the high pressure side is connected with the liquid phase pressure guiding tube, so that the transducer can be in a working environment at normal temperature, and the low temperature liquid can be fully vaporized. In order to adjust the instrument zero position and replace the instrument, a balance valve should be installed between the high and low pressure sides of the differential pressure transducer. After the differential pressure transducer is installed, the zero position should be adjusted, then open the gas pressure pilot valve PL, and adjust the zero position again under the working pressure. Then open the liquid phase pilot valve PH, wait a moment to fully vaporize the cryogenic liquid, and then close the balancing valve to put the pressure transducer into operation. When checking or zeroing during use, first open the balancing valve to balance the pressure on the high and low pressure sides of the differential pressure transducer, then close the liquid phase pressure regulating valve to check or adjust the zero position. If the measured vaporized gas of the liquid is in danger of coming into contact with air, certain safety measures should be taken during maintenance.

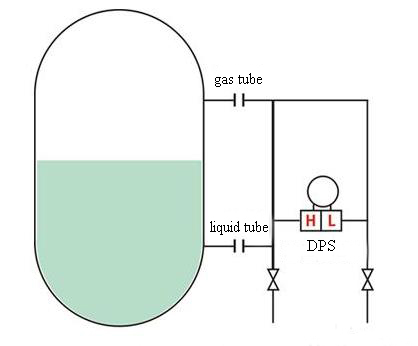

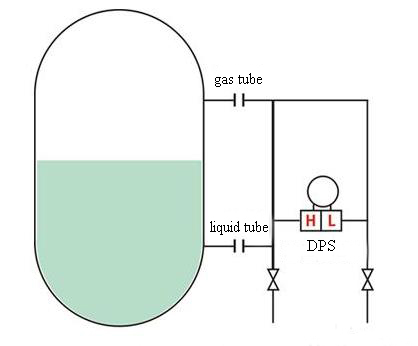

Now we introduce a simple installation method, which is using a tube to connect the air tube to the liquid tube as shown in figure. It can be seen from the figure that the gas generated by the measured liquid vaporization rises along the tube to the top of the container. The liquid flows down the tube. This tube can be selected as a Ф 14 × 2. For corrosive medium, select a stainless steel tube. This method is also feasible for liquid level measurement of low boiling liquids using the differential pressure method. The most important thing is that it does not have strict requirements on the installation position of the differential pressure sensor, which is convenient for on-site construction.

PH=Hx × ρ + Px ; PL=Px

P=PH + PL=(Hx × ρ + Px ) - Px=Hx × ρ, its range: ∆P=(Hx × ρ + Px), then the correspondence between the differential pressure and the current is as follows.

The differential pressure transducer should be installed at a position higher than the highest liquid level, and the high pressure side is connected with the liquid phase pressure guiding tube, so that the transducer can be in a working environment at normal temperature, and the low temperature liquid can be fully vaporized. In order to adjust the instrument zero position and replace the instrument, a balance valve should be installed between the high and low pressure sides of the differential pressure transducer. After the differential pressure transducer is installed, the zero position should be adjusted, then open the gas pressure pilot valve PL, and adjust the zero position again under the working pressure. Then open the liquid phase pilot valve PH, wait a moment to fully vaporize the cryogenic liquid, and then close the balancing valve to put the pressure transducer into operation. When checking or zeroing during use, first open the balancing valve to balance the pressure on the high and low pressure sides of the differential pressure transducer, then close the liquid phase pressure regulating valve to check or adjust the zero position. If the measured vaporized gas of the liquid is in danger of coming into contact with air, certain safety measures should be taken during maintenance.

- How to measure the liquid level of cryogenic liquid when the differential pressure transducer installation position is limited

Now we introduce a simple installation method, which is using a tube to connect the air tube to the liquid tube as shown in figure. It can be seen from the figure that the gas generated by the measured liquid vaporization rises along the tube to the top of the container. The liquid flows down the tube. This tube can be selected as a Ф 14 × 2. For corrosive medium, select a stainless steel tube. This method is also feasible for liquid level measurement of low boiling liquids using the differential pressure method. The most important thing is that it does not have strict requirements on the installation position of the differential pressure sensor, which is convenient for on-site construction.